Finding the GH₂ solution requires just one tool?

Hydrizon KnowIT

More than software——it’s your CPO for H₂, NH₃, and ROH projects.

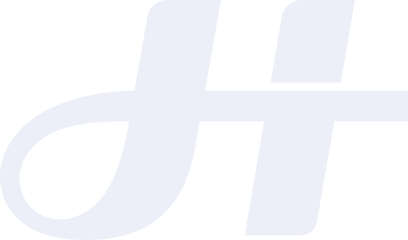

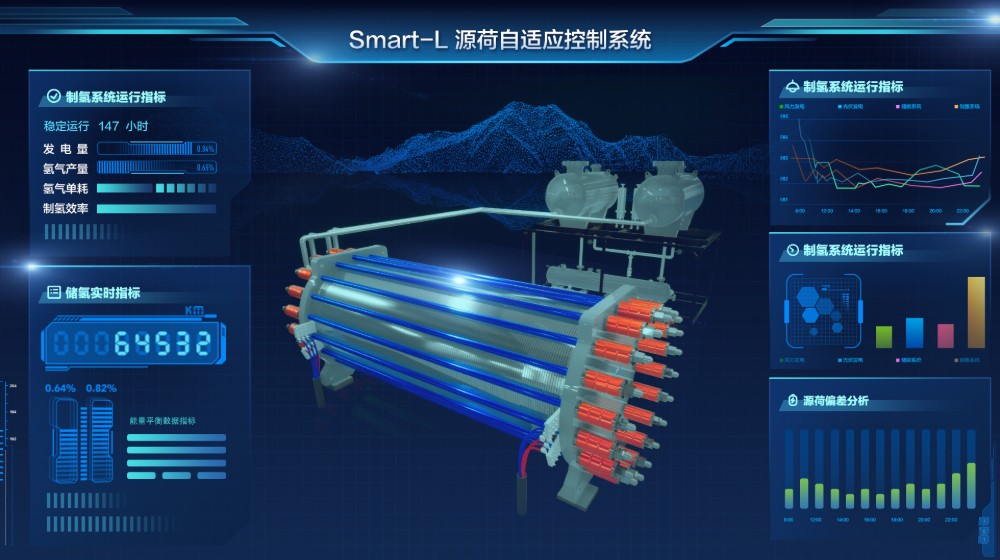

intelligent planning, ratio optimization, seamless implementation

More than software——it’s your CPO for H₂, NH₃, and ROH projects.

intelligent planning, ratio optimization, seamless implementation