More than software——it’s your CPO for H₂, NH₃, and ROH projects.

intelligent planning, ratio optimization, seamless implementation

| Weight | Energy Consumption | Cell Count | Load Range |

|---|---|---|---|

| 45T | 4.1-4.5KWh/Nm³·H₂ | 280-350 | 30%-110% |

Hydrizon Alkaline Electrolyzer Technology Iteration Strategy:

1.Flow field structure: simulation, testing, and iterative optimization

2.Membrane: 15% of total cost, self-manufactured, with 30% cost reduction

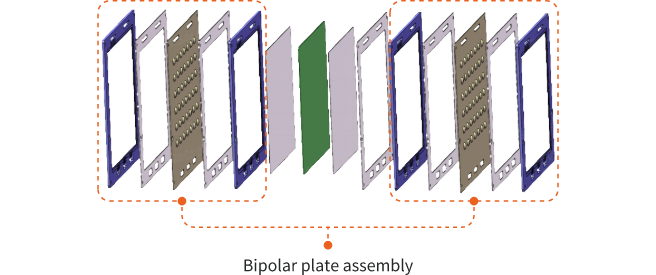

3.Bipolar plates: accounting for 40% of cost, key optimization target

| Weight | Energy Consumption | Cell Count | Load Range |

|---|---|---|---|

| 30T | 4.1-4.5KWh/Nm³·H₂ | circa 350 | 30%-110% |

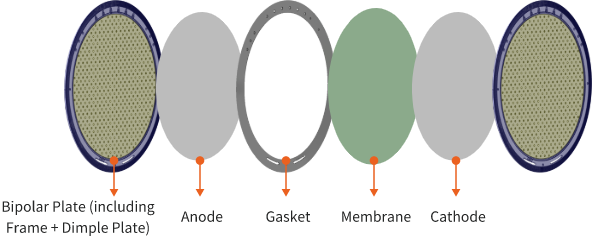

1.Plastic Frame (PSU)

2.Ultra-thin nickel plate stamping (0.5mm): provides flexibility, reduces contact resistance, and enhances corrosion resistance and service life

3.PTFE ultra-thin gasket replaces modified thick gasket

| Weight | Energy Consumption | Cell Count | Load Range |

|---|---|---|---|

| 20T | <4.5KWh/Nm³·H₂ | circa 350 | 30%-110% |

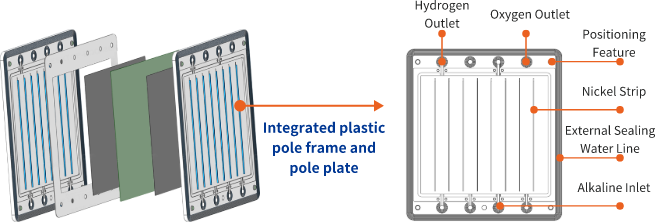

1.Integrated molding of frame and plate, no machining or welding required

2.Embedded nickel strips with adjustable spacing

3.Alignment features to ensure assembly consistency

4.Low hardware investment: injection molding machine

| No. | Title | Type | Patent No. |

|---|---|---|---|

| 1 | Electrode Frame Plate with Embedded Metal Sheet and Electrolyzer | Invention | CN118932367A |

| 2 | Electrode Frame Plate with Elastomer and Electrolyzer | Invention | CN118932367A |

| 3 | Integrated Plastic Electrode Frame Plate with Pressure and Flow Regulation Structure and Electrolyzer | Invention | CN118932367A |

| 4 | High-sealing Integrated Plastic Electrode Frame Plate, Electrolyzer Cell, and Electrolyzer | Invention | CN118932367A |

| 5 | Electrode Frame Plate and Electrolyzer Using the Same | Invention | CN118932367A |

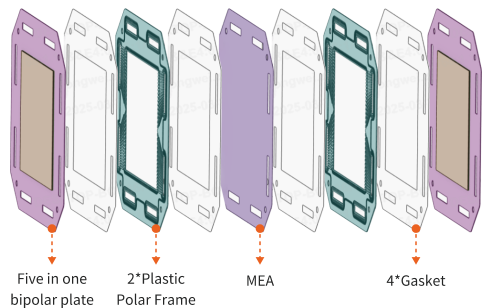

1.Integrated “Five-in-One” Bipolar Plate Structure: Comprising an ultra-thin nickel plate, multi-layer nickel mesh, and nickel felt in a unified fixed assembly. This design effectively reduces contact resistance and simplifies installation and alignment.

2.PSU Plastic End Frame: Enables flexible construction of sealed water circuits and inlet/outlet flow channels; features lightweight design and cost efficiency.

3.Modified Ultra-Thin PTFE Gasket: Balances mechanical strength with excellent sealing performance, enhancing system reliability.

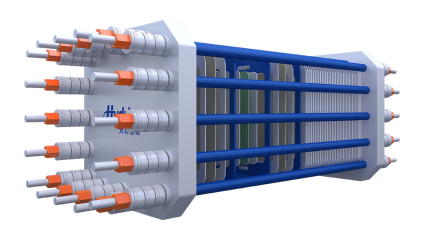

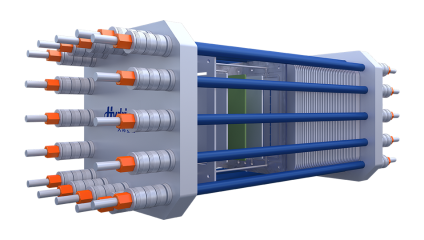

4.Modular Electrolyzer System Design (1–50 Nm³/h): Adopts a series-based configuration allowing flexible stacking to suit diverse customer application scenarios.

5.Customizable Solutions: Flexible system configuration available based on customer-specific requirements, offering tailored design and component options.

| System Conditions |

10-120% Load Range |

65℃ Operating Temperature |

≤20Min Cold Start Time |

≤4.6kw.h/Nm³ Energy Consumption (DC) |

|---|---|---|---|---|

| Out Conditions |

1~200Nm³ Hydrogen Production Capacity |

3.0MPa Hydrogen Output Pressure |

>99.9%(v/v) Initial Hydrogen Purity |

>99.999%(v/v) Product Hydrogen Purity |

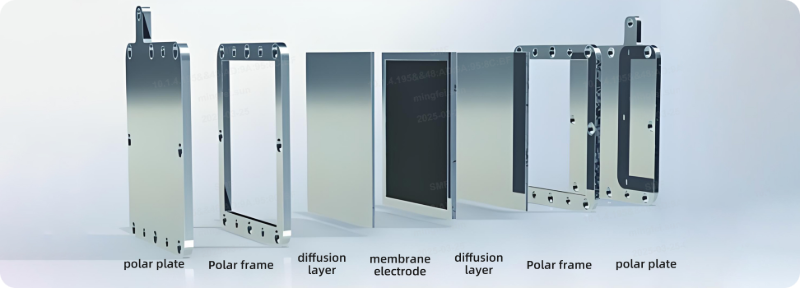

1.Etched Monolithic Bipolar Plate Design One-piece etched bipolar plates offer high sealing reliability and structural integrity.

2.Integrated Sealing Gasket Bonding Streamlined assembly with reduced failure risk and higher dimensional tolerance.

3.Continuously Optimized Flow Field Design Reduces power consumption and improves O&M cost-efficiency.

4.High-Performance Pressure-Resistant MEA Enhances system safety, efficiency, and operational lifespan.

More than software——it’s your CPO for H₂, NH₃, and ROH projects.

intelligent planning, ratio optimization, seamless implementation